CFD based Probabilistic Blast Overpressure Study

We have strong experience in performing advanced Computational Fluid Dynamics (CFD) studies for predicting explosion overpressures and recommending on design improvements to reduce potential for gas accumulation, prevent explosion overpressures exceeding design loads and further design structures and buildings to withstand explosion overpressures and impulses for protecting people and assets.

Such CFD studies are very crucial for Offshore Oil & Gas platforms, FPSO, FSO, FLNG and in congested facilities onshore such as Refineries, Petrochemicals and some Chemical Plants.

CFD Explosion Consequence Analysis

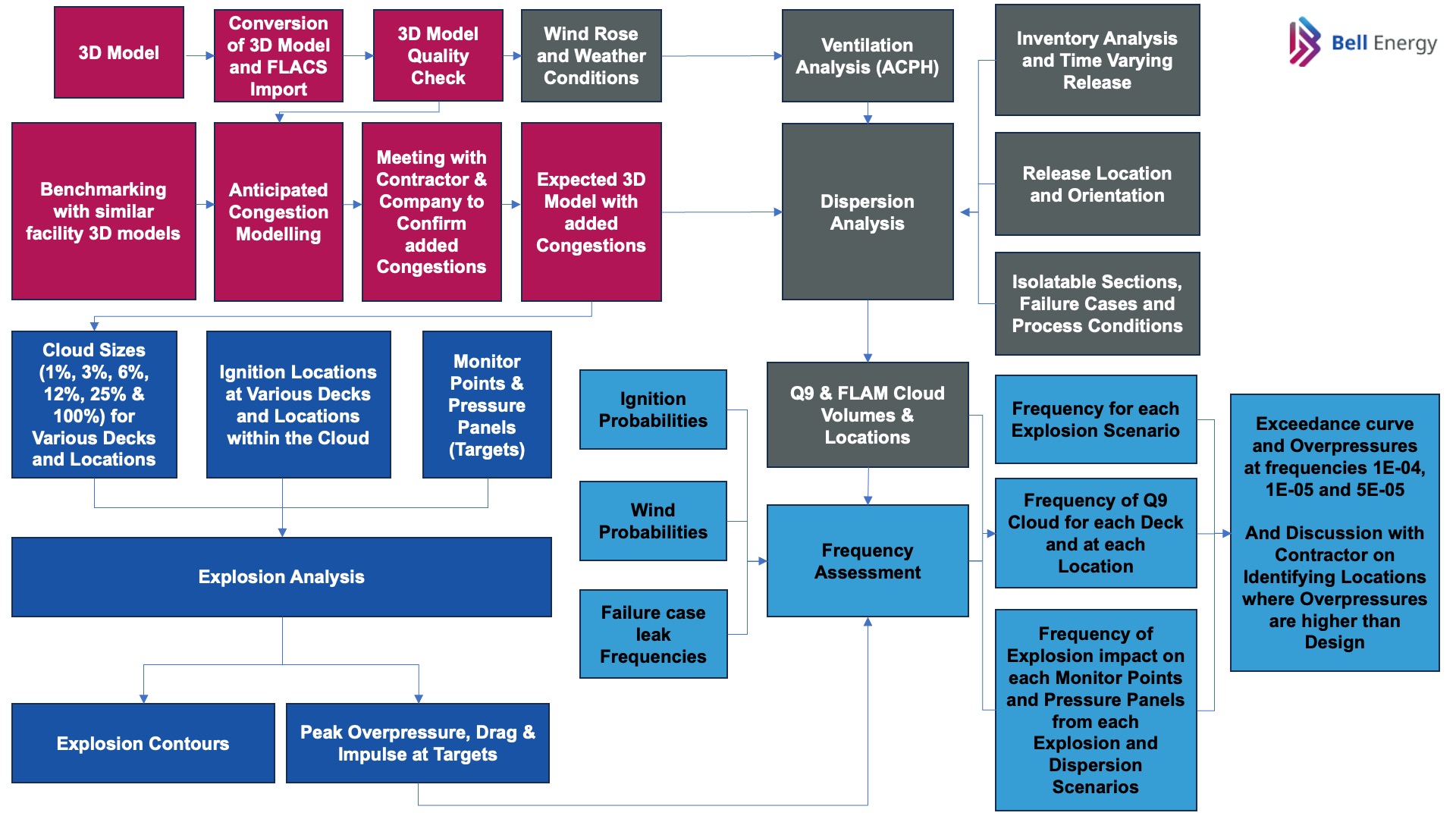

In this study, we identify congested regions and determine the various gas cloud shapes and sizes that have the potential for accumulation. For these specific gas clouds that are determined based on credible leak sizes, explosion overpressures, impulse strength and drags are determined using CFD. This is a consequence based study and can be used during early phases of the project to improve ventilation within congested regions and minimize explosion potentials.

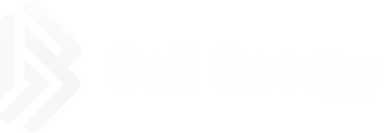

Anticipated Congestion Modeling

Where 3D models are at incipient stages of development, “Anticipated Congestion Modeling (ACM)” is performed by benchmarking the 3D model with other similar facilities.

We perform anticipated congestion modeling based on the library of 3D models of real Oil & Gas facilities that we posses within our library.

We complement this with a detailed brainstorming workshop in the presence of piping and structural engineers to determine the extent to which the ACM represents reality.

Probabilistic Blast Study

The objective of a probabilistic blast study is to determine the overpressure exceedances at various targets such as buildings, Safety Critical Equipment, critical structures and escape routes to name a few.

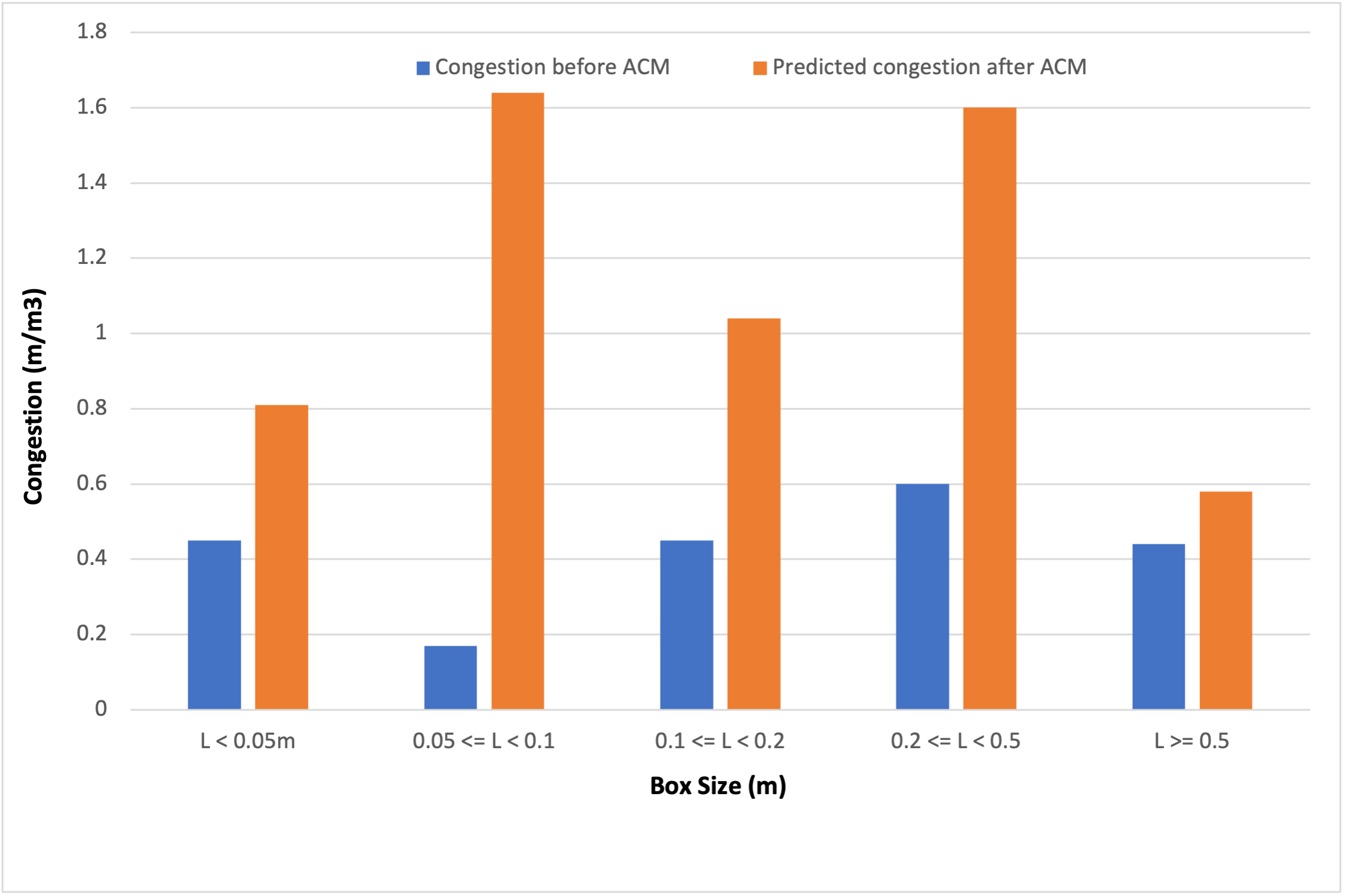

As part of this study, we perform various tasks as shown in the block diagram presented below. These activities start reviewing the 3D model and performing quality checks.

If the model is not matured enough with adequate congestions especially arising from small bore piping, tubings, cable trays etc, Anticipated Congestion Modeling is performed. Subsequently, information is reviewed to determine the volume of gas that can be potentially involved in an explosion for various types of releases within the facility.

The further steps include Ventilation Assessment, Frequency Estimation, Ignition Probability & time estimation, dispersion analysis, determining explosion overpressures for various sizes of gas clouds at various locations within the congested regions, determining explosion overpressures from various ignition locations, post processing etc.

Probabilistic Blast Study is a very detailed study that provides design inputs to structural, mechanical and piping engineers. Such studies may be performed during FEED phase and subsequently revalidated during the Detailed Engineering phase.

Bell Energy uses FLACS software developed by GEXCON for performing CFD based dispersion and explosion studies. Bell Energy have developed in-house tools to map dispersion scenarios with explosion scenarios based on cloud sizes. This helps in significant reduction of time for post-processing.

What are the benefits of CFD based Explosion study?

- Improve ventilation of regions by re-orienting equipment to reduce explosion overpressure potential

- Determine the Design Accidental Loads for various frequencies and make better structural design decisions

- Optimize cost of explosion design of buildings, critical structures and static equipment supports

- Improve escape and evacuation capabilities by identifying single point of failures due to explosions